Special Motors Design

The design of special motors always starts from a customer’s request. Often, the electric motor is designed together with the application in which it will be used. This allows the possibility to study particular geometries or performances, which optimize both the cost of assembly and the general performance.

Definition of the project

During the first step of the motor development, Ride’s technical and sale Office define customer’s requests and the eventually technical solutions.

Design, prototypes and test

The characteristic curve of the motor represents the most important information. Trough the characteristic curve we can decide the size of a Dc electric motor or a Dc gear motor. For what concerns planetary gear motors, the characteristic curve establishes even the gear ratio and the gearbox number of stages.

This data allow to define a motor able to support the working cycle, the duty cycle and then, the life test that the application requests.

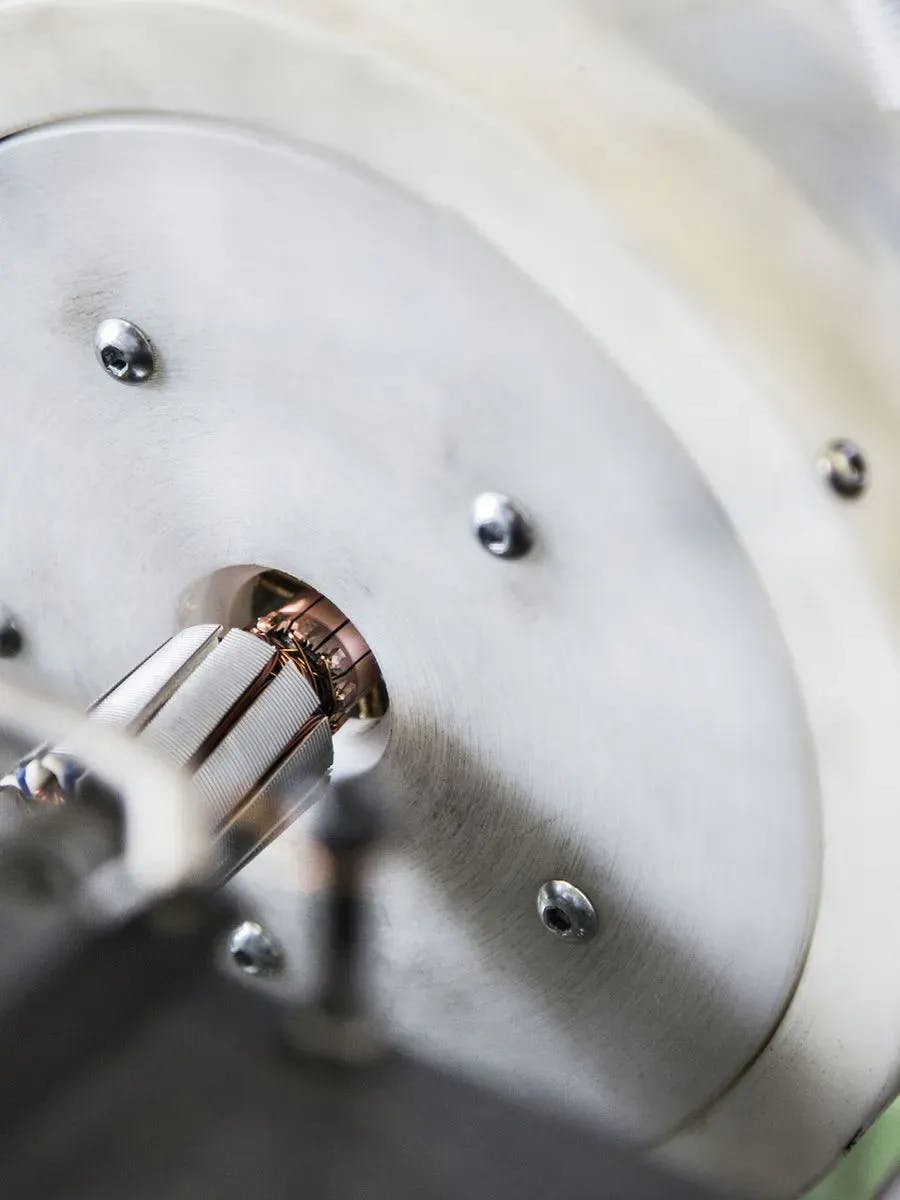

After the design, must be realized the prototypes. They represent the test before ordering the mass production tools.

The definition of the prototypes is realized both trough the combination of existing components, completed by machined elements or prototype tools. Often the prototypes haven’t mechanical characteristics to support a full cycle of life. They are necessary to verify the performances and the assembly in the application.

The following steps concern the detailed definition of coupling flanges, assembling processes, cables design (with the connector), kind of encoder and EMC filter.

Normally the customer takes care of the life test. When it’s necessary, Ride offers to run the tests also in its laboratory.

Production

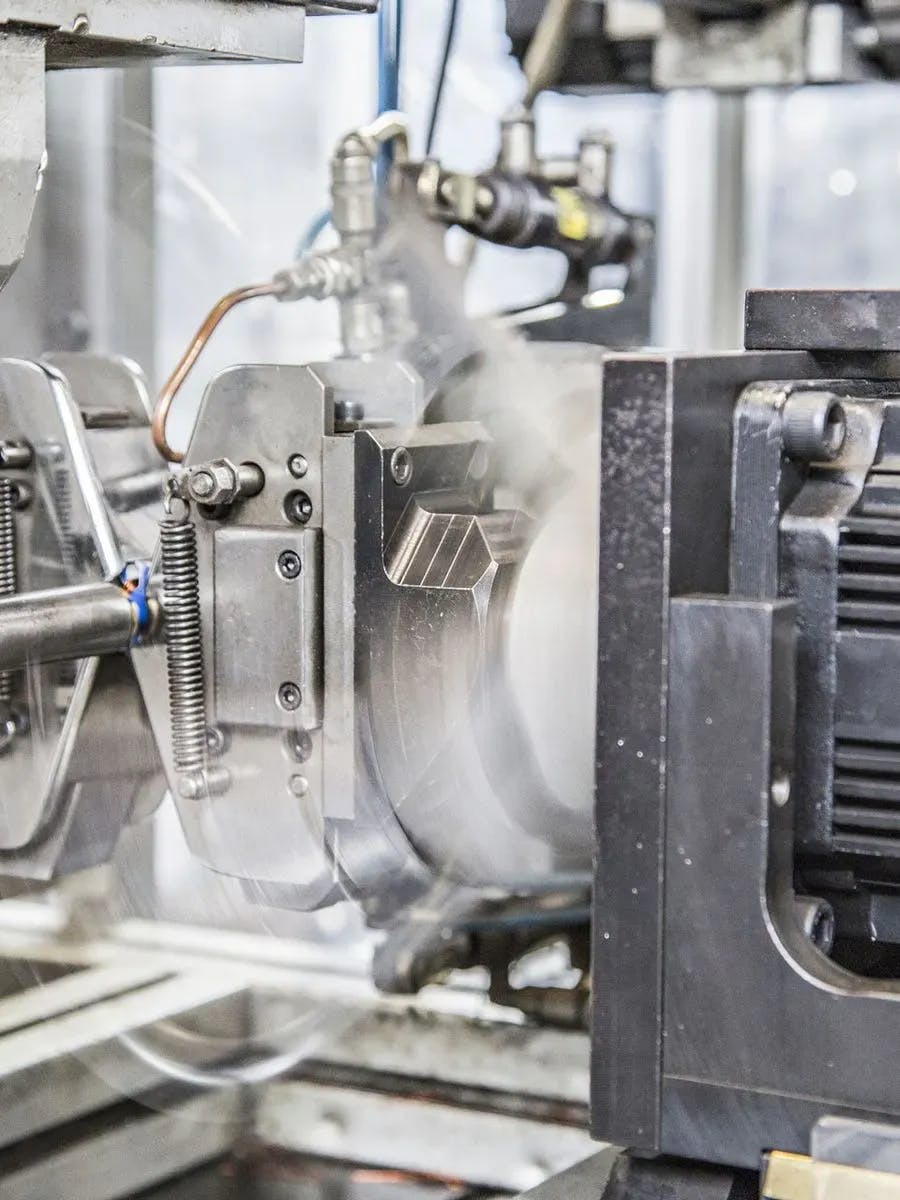

The start of the production implies to verify every single component and each assembling phase. The equipment must be proved to homologate the right functioning.

For the processes setting it’s organized the realization of a pre-series productions to verify that in every production’s phases there are not mistakes or problems. At the end of the analysis and of the last definitive corrective actions the mass production can start.

Direct Current Electric Motors

Ride crafts DC motors and gearmotors for every industry, ensuring tailored performance and reliability.