Maintenance

Dc electric motors don’t need any sort of maintenance. The life test certifies that a Dc electric motor or a Dc gear motor satisfies the log-life performance without any intervention for the maintenance of Ride’s electric motors.

Resistance of the components

The applications for which Dc electric motors are chosen have lifetime requirements that are compatible with the lifetime of the assembled components. The strains from the point of view of applied load that the motors receive during the functioning are verified in the life test.

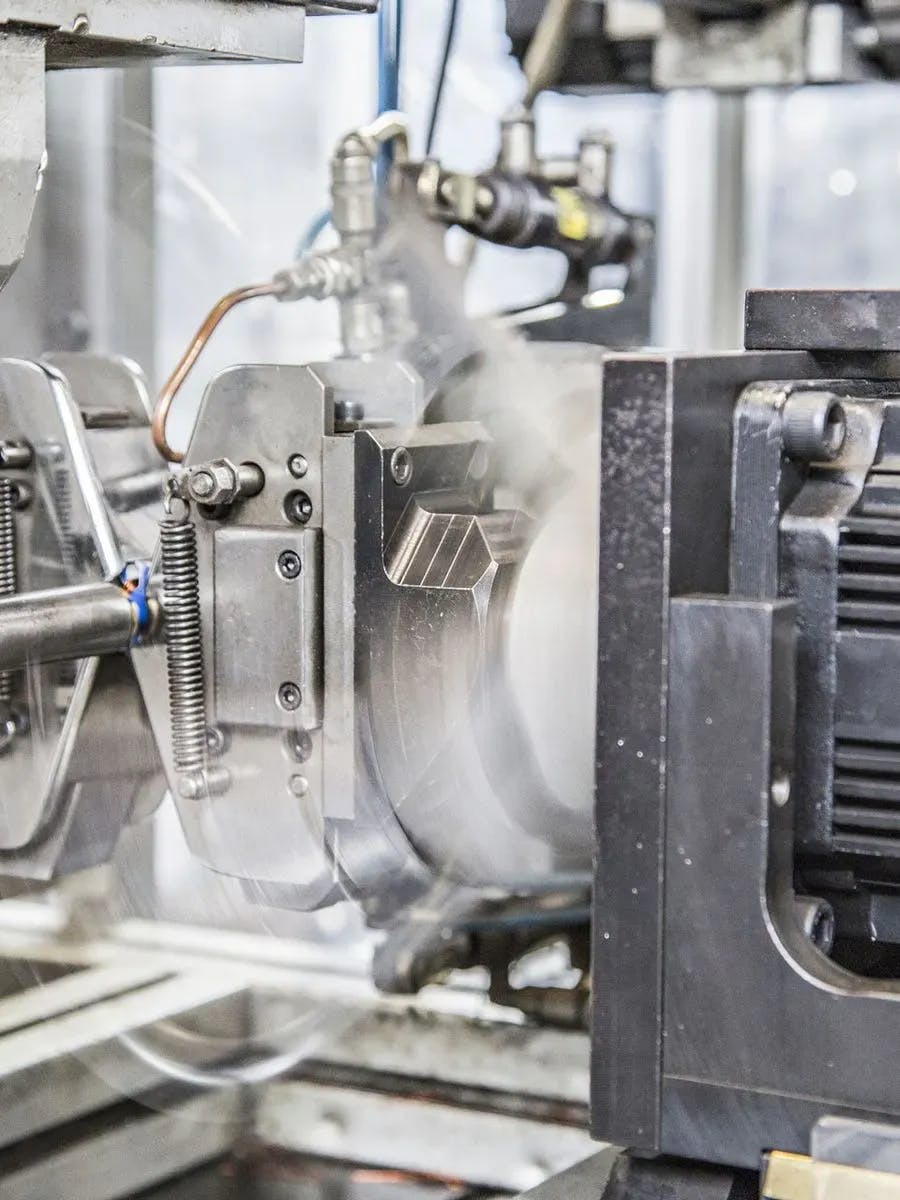

The main components tested during life-tests are: brushes, the ball bearing, the shaft and the gears. Those components, subjected to mechanical wear, need to be properly tested and produced from reliable suppliers.

The importance of life test

To prevent mechanical wear or premature breaking it’s very important the life test.

Unfortunately each application, even if similar to another one, can present different criticality. For this reason, the same Dc motor, Dc gear motor or Dc planetary gear motor needs to be tested in each new application in which is used.

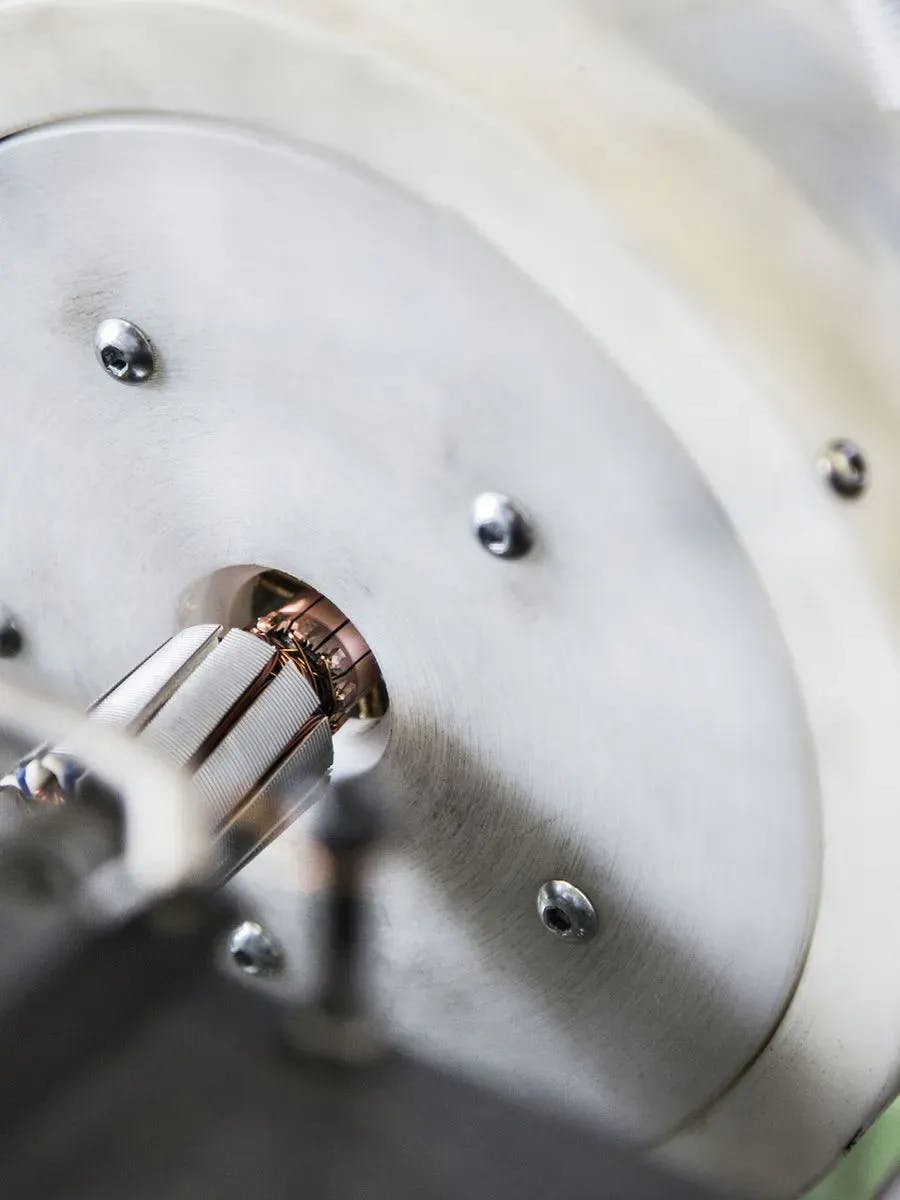

This prerogative allows, since it’s not necessary to have access point in the motor for the maintenance, to concentrate every effort on an efficient assembly.

Discover our motors

Direct Current Electric Motors

Ride crafts DC motors and gearmotors for every industry, ensuring tailored performance and reliability.